Most recently established department in BWC Group is Processing Technology department started 2018 with activity. Numeric control CNC machines of lattest generation with all auxiliary programmable machines are good base of this business founded with anticipation of client’s needs and our efforts to fullfil all kind of client’s demands. Second base is production of high-quality plates in our POLYPLATE department, which from we are abble to place a supperior product on the domestic and international market. Main assortment are product such:

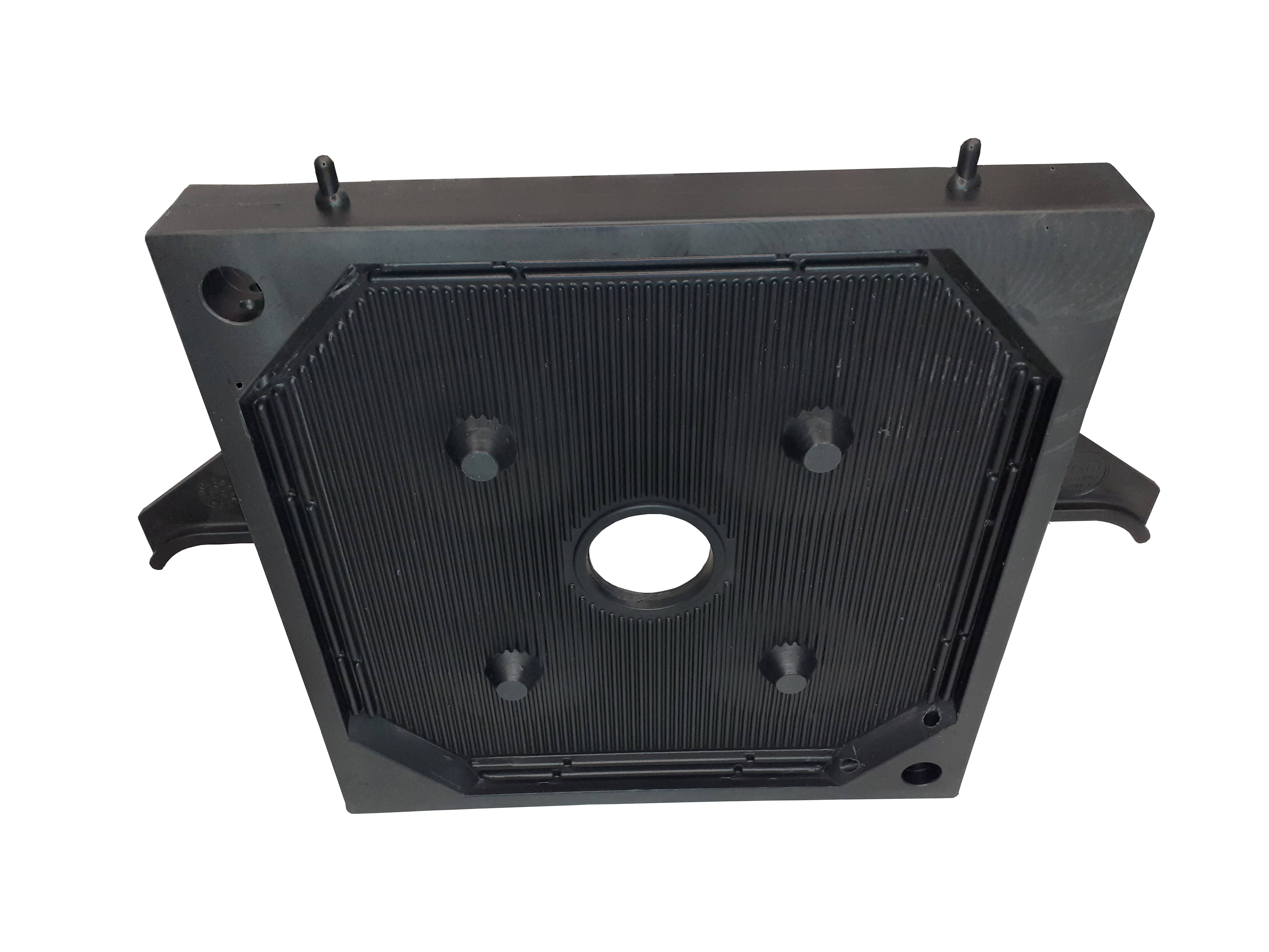

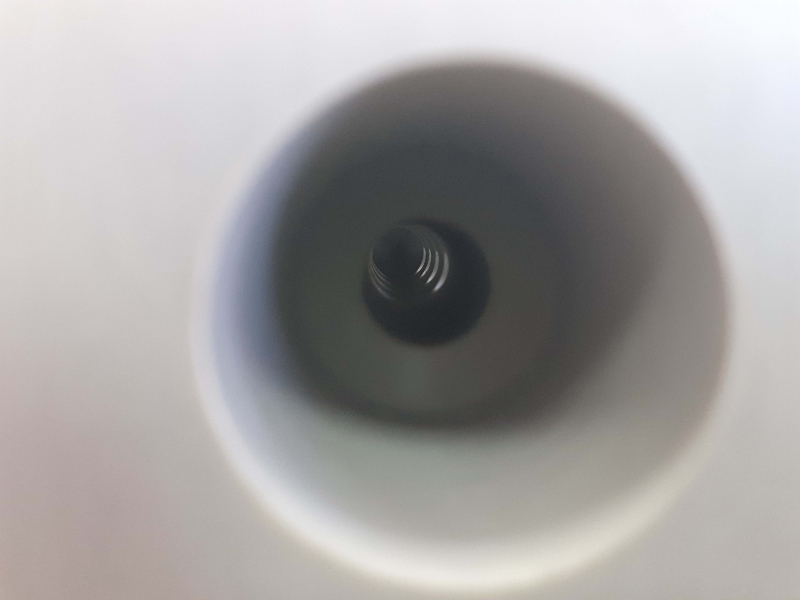

- Water filter press plates – with all standard dimmesions, variations and details

- Round plastic products – with diverse threads, pulleys, flanges, bungs…

- Plastic plate products – holders, sliders, guiding rods, hadles…

- Products and vessels produced with plastic welding technology

- Custom-made products

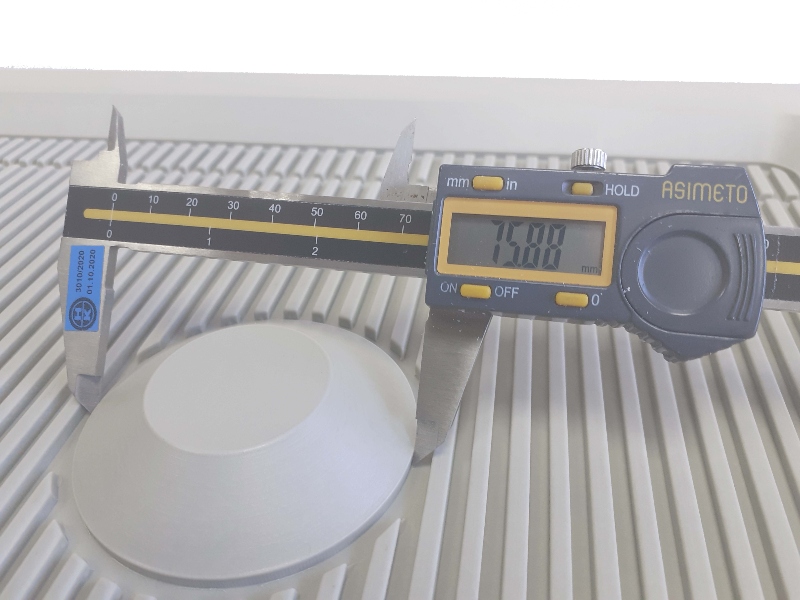

Strategic and most important products are water filter press plates with compleatelly export orientation. Modern production technology and materials used for the product, overcomes the quality can be found on the market. Pressed polypropylene as plate semiproduct with CNC machine processing and finally thermic treatment are steps to achieve supperior quality. Made in all standard dimmensions for filter press machines of all world producers, offers unlimited possibilities for our clients. Very severe final control procedure for each piece, accomplish all tolerance demands, which are narrow in first place. For new customer we can do pilot piece based on drawing, sent model or even a sketch, which can be improved on customer’s wishes.

MATERIALS AND TECHNOLOGY

Filter press plates are made of basic homopolymer polypropylene pressed plate. High pressure pressed plate have better mechanical features than plates made from other technology, better toughness, stiffness and processibility. Plate shape and relief is processed on three axis control CNC line. Thermical final treatment makes the surface smooth without sharp edges.

Plates can be made from HDPE and UHMPE and some more raw materials depending on customer’s needs.

DIMMENSIONS

Standard plate dimmesions we can process are: 250; 400; 470; 500; 630; 800; 1000 and 1200 mm. Plate thickness can be 40 mm. or 60 mm. or even bigger upon customer’s needs.

MODELS AND TYPES

Filter plates are chamber type plates with versions of open and closed type. Basic plate is made of one layer.

AUXILIARY PRODUCTS

Our offer includes all auxiliary products for filter plates and presses as well like handles, guidings, diverse plastic o-rings and all tools and necessary accessories.

ENGINEERING AND SUPPORT

BWC Group from our Processing Technology Department can offer engineering service to all our customers. We are on disposition to offer the best solution the customer needs based on big data base we have and experience from other projects. Our engineers are going to turn clients ideas into reality and high-quality product on mutual satisfaction.