TECHNICAL SHEETS

Pressed sheets:

- Polypropylene, PP

- Polyethylene, PE

- High-molecular weight polyethylene, HMWPE

- Ultra-High-molecular weight polyethylene, UHMWPE

- Polystyrene, PS

- Other products

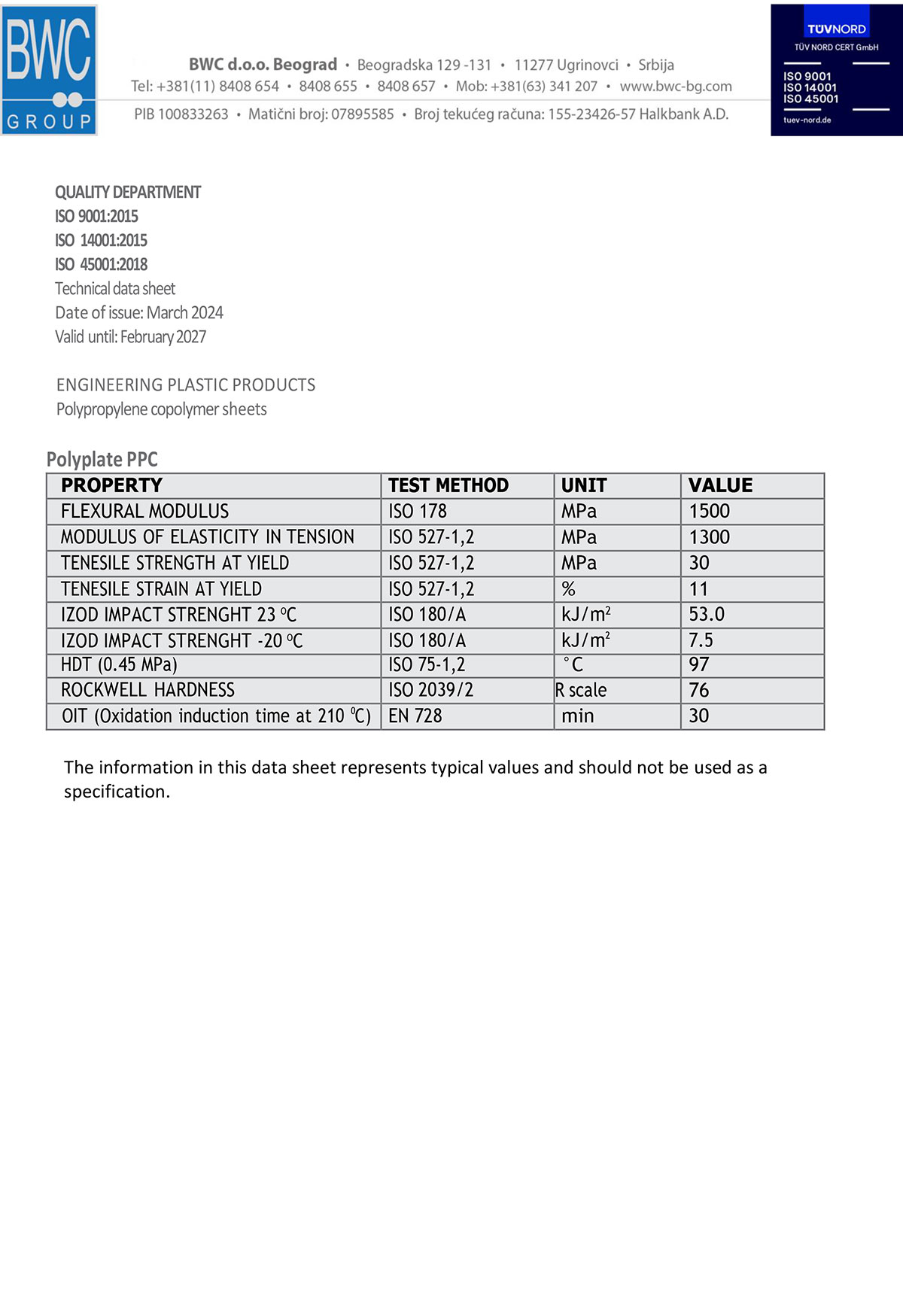

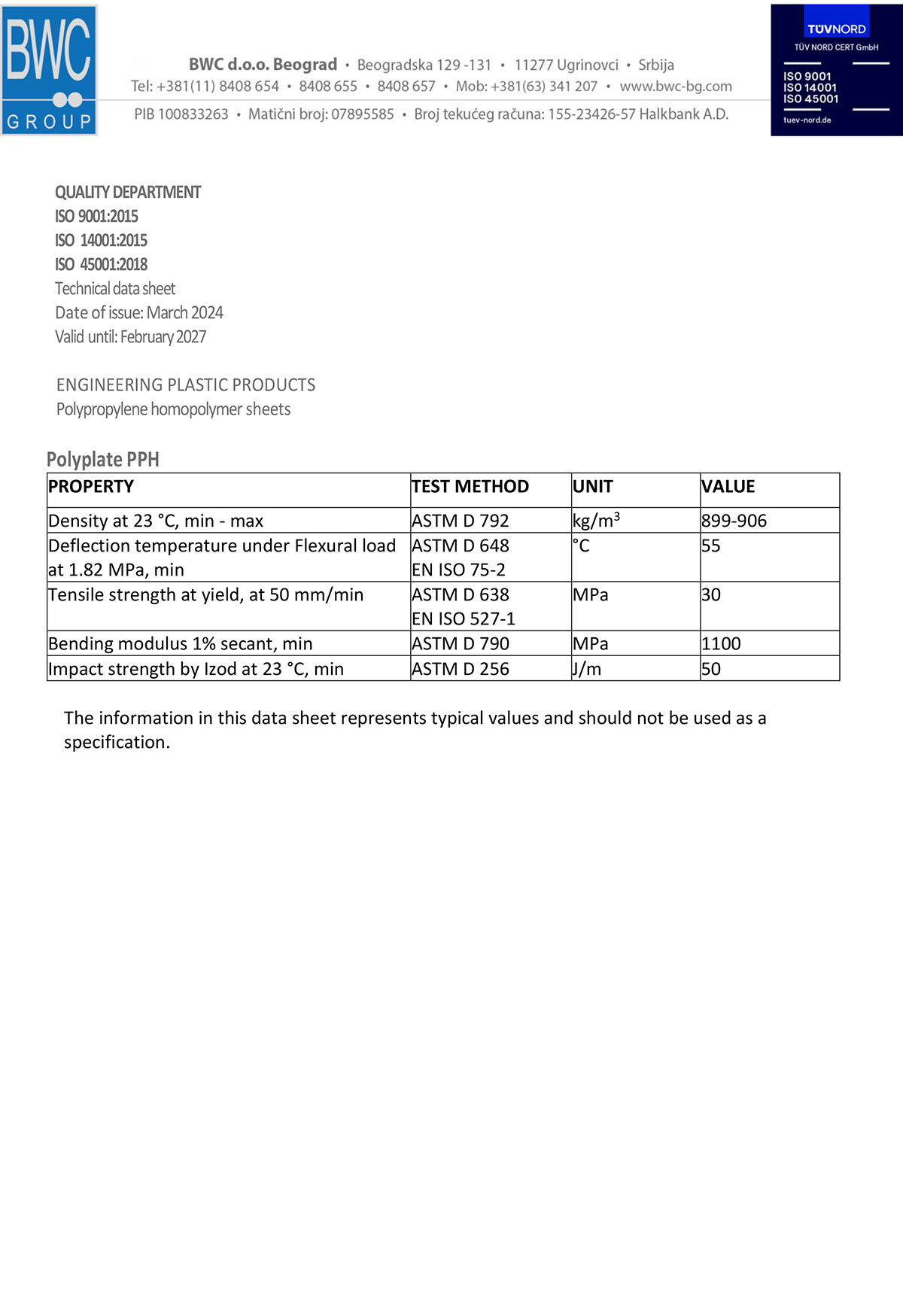

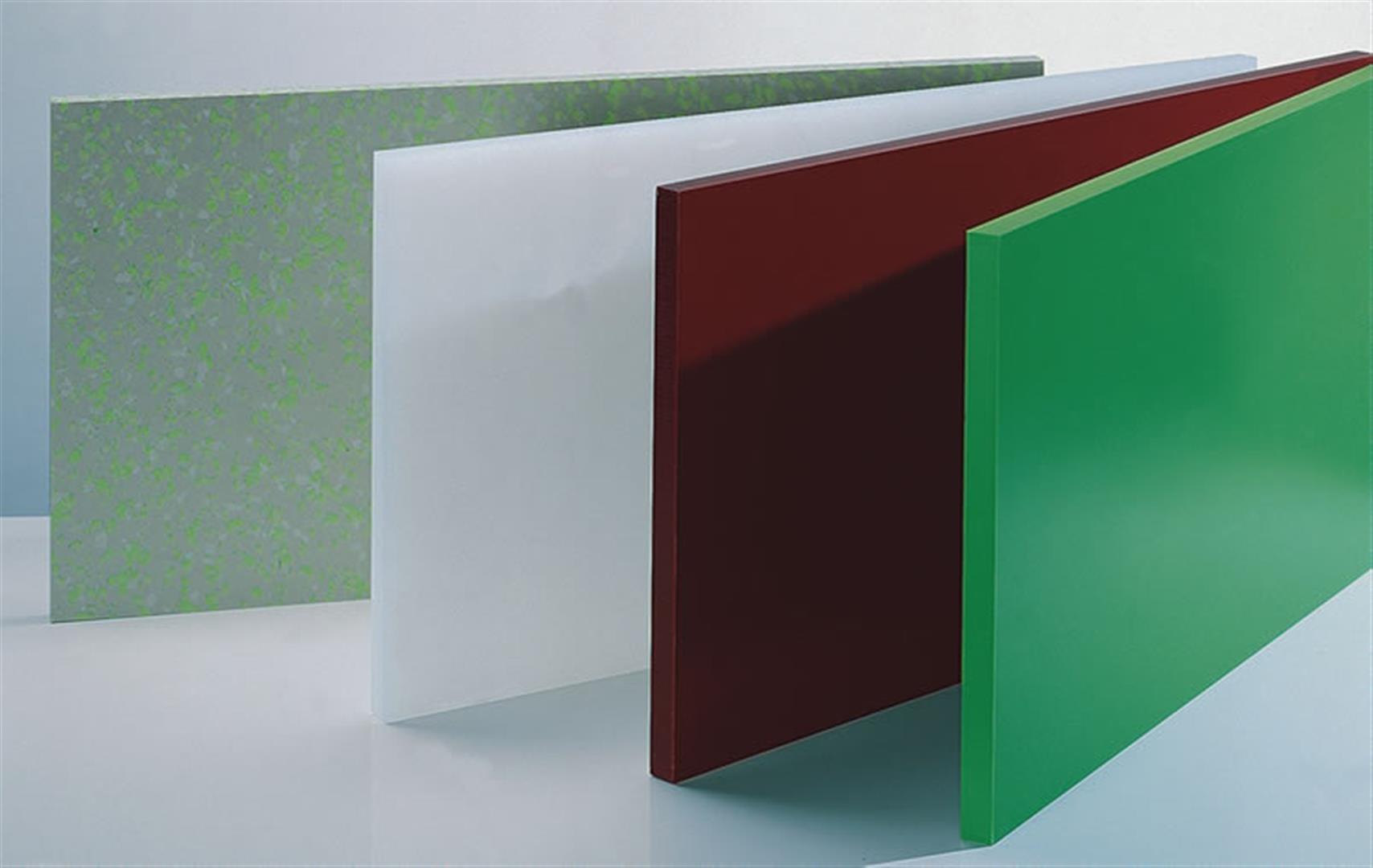

a) PPH sheets natural and coloured

b) PPC sheets natural and coloured

c) PPC relief sheets

Sheets are produced in standard dimensions 2500 × 3000 mm with thickness from 8 mm to 100 mm.

Polypropylene is one of the lightest thermoplastic materials.

It is characterized by a high resistance to chemicals, PPC is resistant to temperatures from – 20 ºC to 90 ºC while PPH is resistant to temperatures from 0º C to 100 ºC.

It is convenient for thermal and mechanical processing, it has excellent dielectric and insulating properties.

PP does not absorb water and is physiologically flawless.

Our PPH boards are mainly made of Hipolen EH-7 which is produced in Hipol, Odžaci.

PPC boards are mainly made of materials Eltex TUB-433 NA00, Mosten EH 501 and Tipplen K 850.

Sheets application:

a) All types of tanks

b) Wastewater treatment systems

c) Galvanization baths

d) All types of cutting boards (textile, shoe industry)

e) Filter elements in the chemical industry

f) Drainage elements in the paper industry

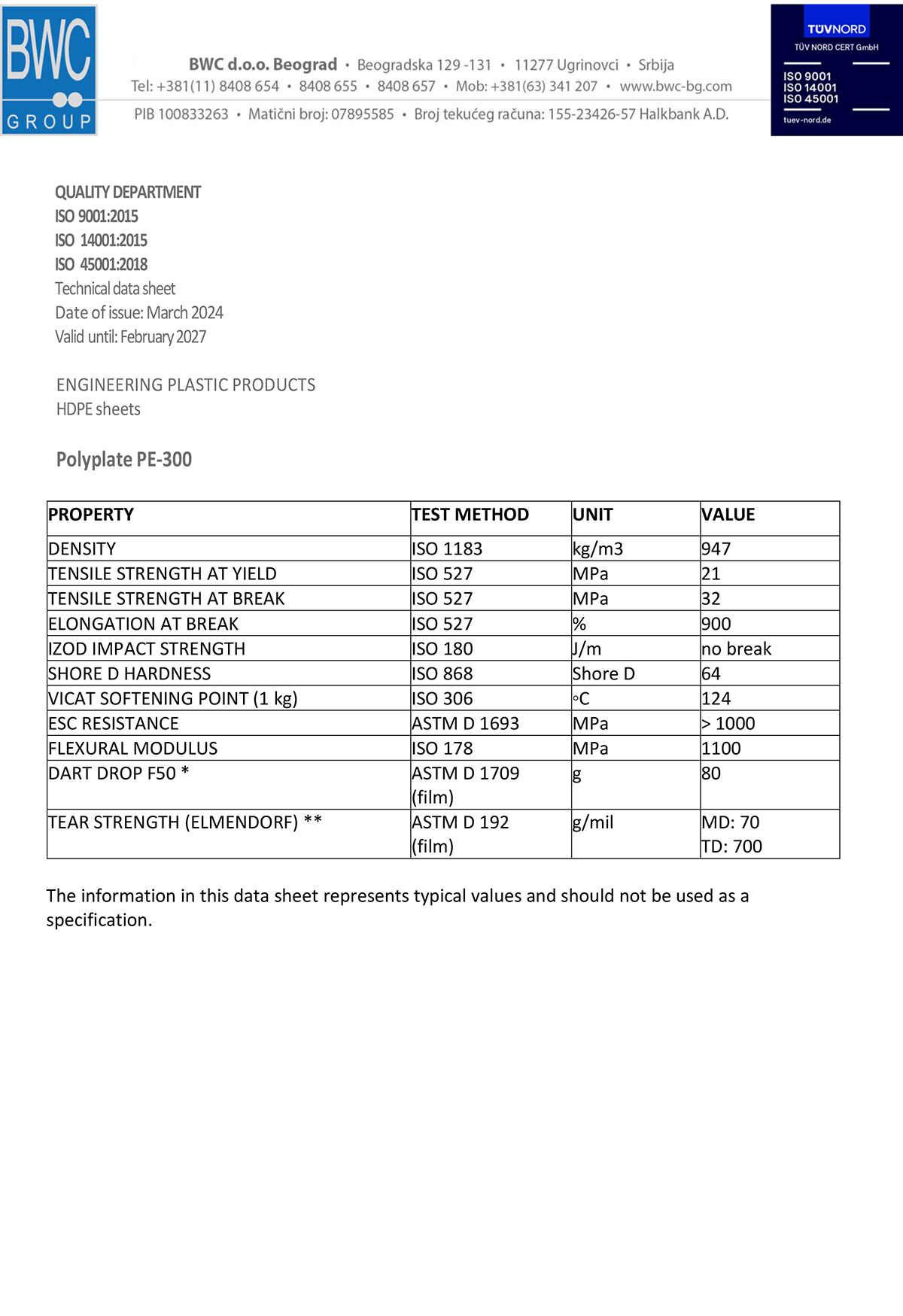

a) HDPE sheets natural and coloured (PE-300)

b) HDPE sheets black (PE 80 and PE 100)

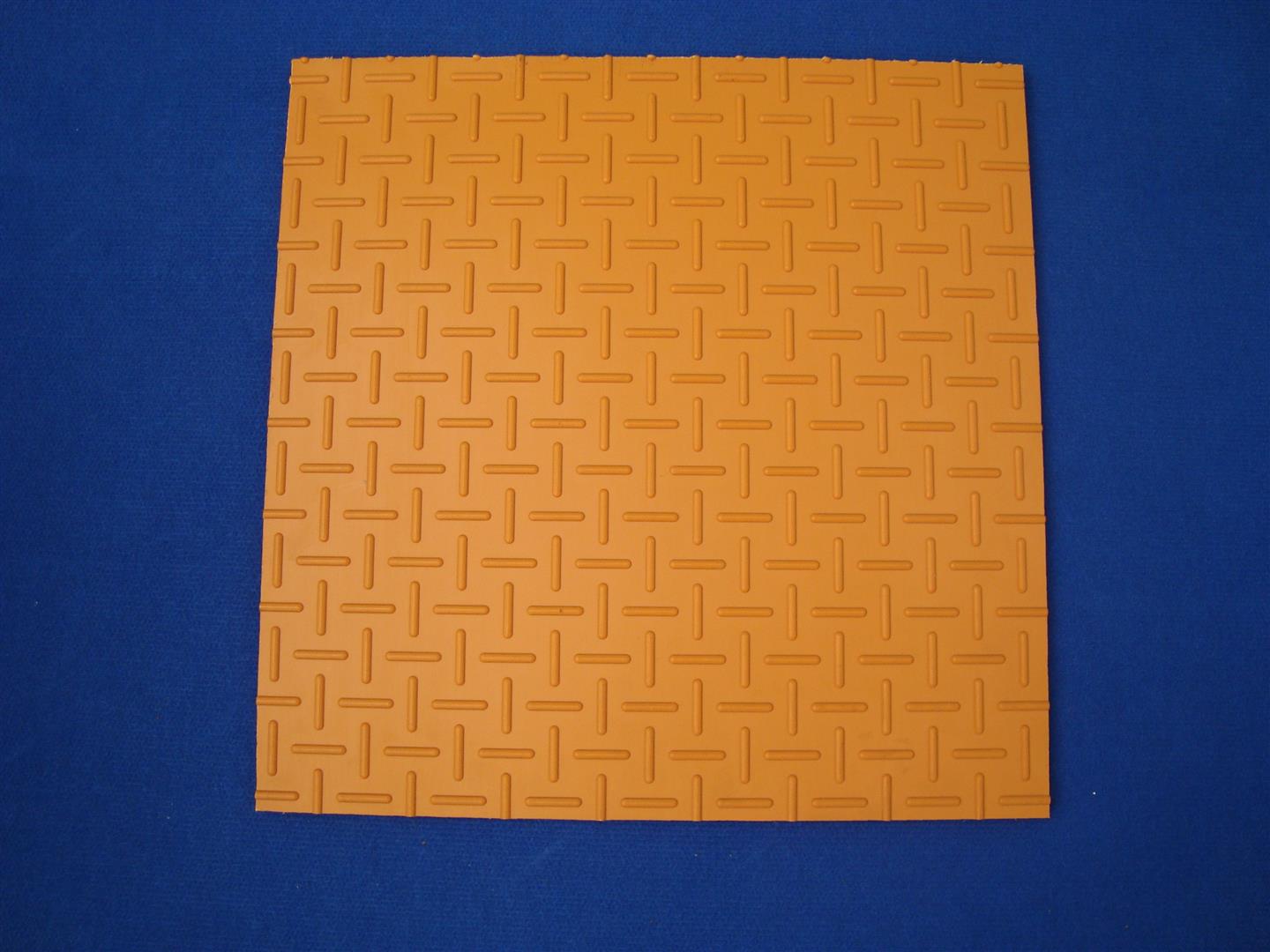

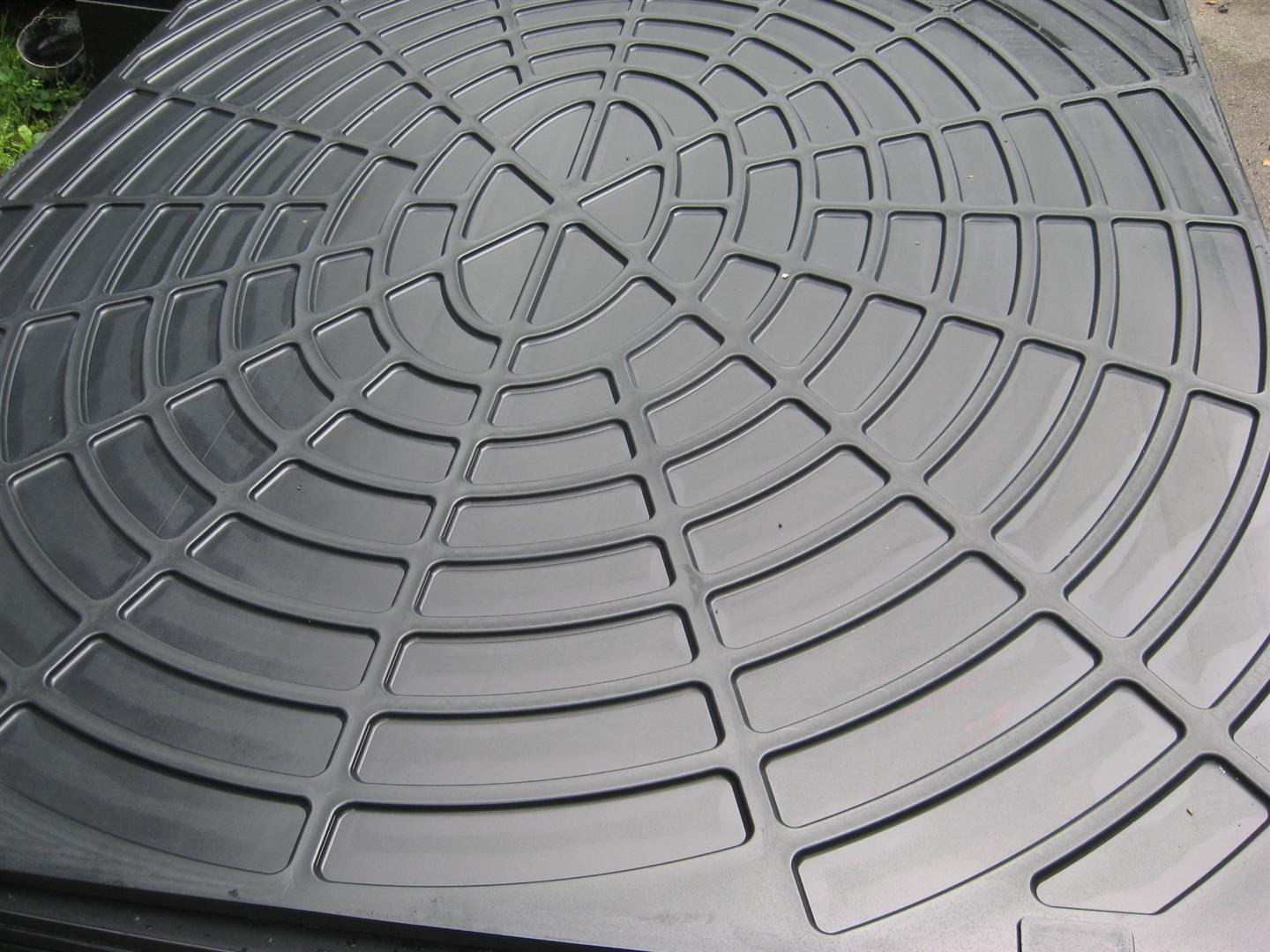

c) HDPE double-side relief sheets

d) UHMWPE double-side relief sheets

Relief sheets are made of high density polyethylene (HDPE) or Ultra High Molecular Weight polyethylene (UHMWPE).

Sheets are produced in two standard dimensions:

a) 3000x2500x40 mm

Weight of one sheet: 300 kg

b) 3000x2500x22 mm

Weight of one sheet: 176 kg

On both sides, relief sheets have a significant application as part of the installation of TEMPORARY ROADS on inaccessible terrains (mud, sand), then for the installation of mats on oil fields.

These boards can be used for temporary PARKING. Such parking was in the last Olympics in London.

Sheets withstand very well all ambient temperatures in the range from -80 ̊ C to +80 ̊ C.

Load-bearing capacity of the sheets is up to 150 t.

Application:

a) All types of tanks – Water tanks

b) Food industry- Cutting boards

c) Mining, Energy – Silo lining

d) Chemical industry- Filter elements

e) Utilities – fittings for connecting PE pipes

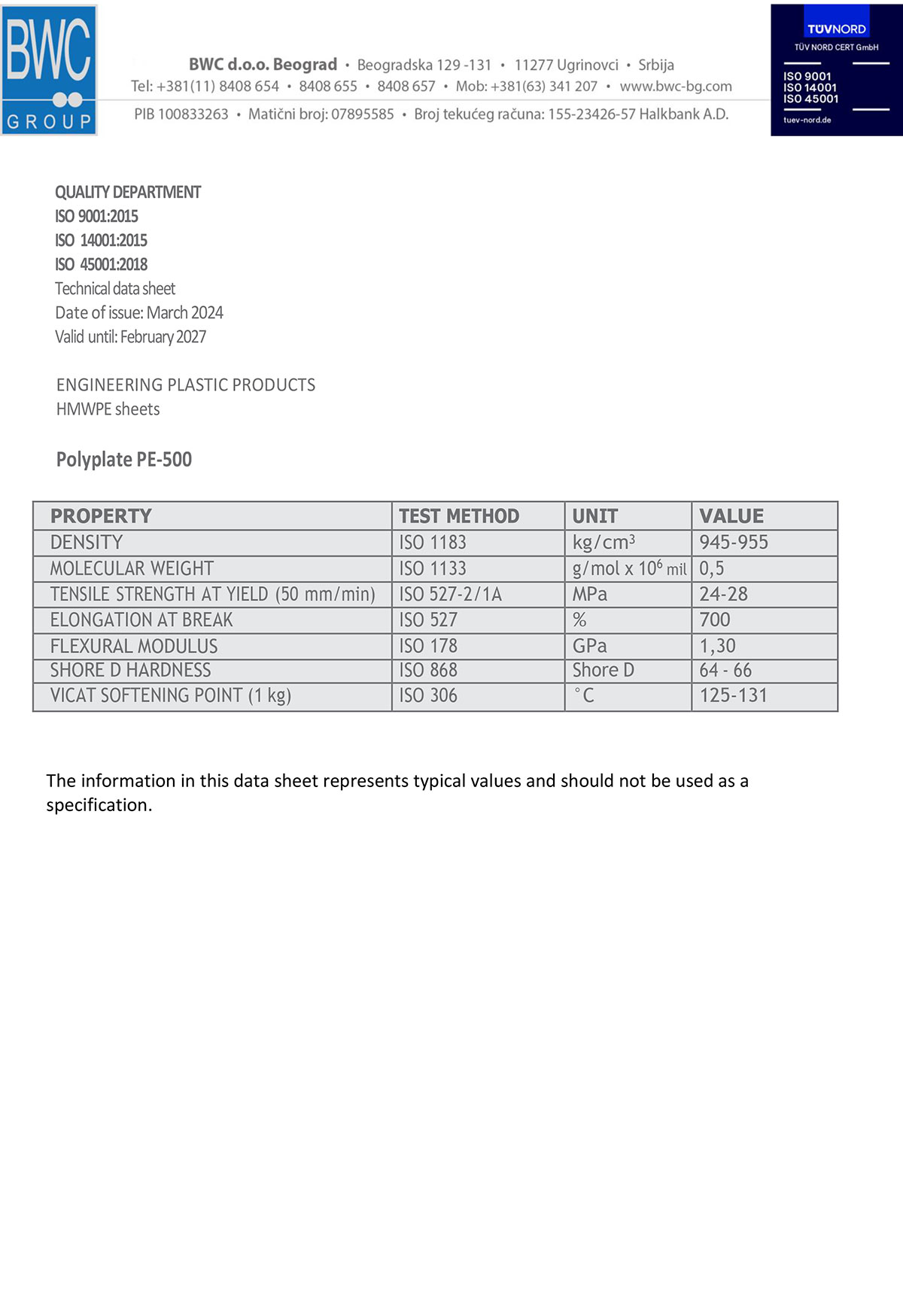

HMWPE sheets are produced in dimensions 2500 × 3000 mm, thickness from 10 mm to 100 mm.

High molecular weight Polyethylene PE 500 has excellent mechanical properties, it is very resistant to a large number of chemical reagents. It is an excellent insulating material.

It is very resistant to low temperatures. It retains all its properties in the temperature range from – 100 º C to + 60 º C.

Polyethylene PE 500 is physiologically flawless, does not absorb moisture and has high impact resistance.

It has a distinct white color and is therefore suitable for use in the food industry.

Molecular weight of PE 500 is approximately 500000 g/mol.

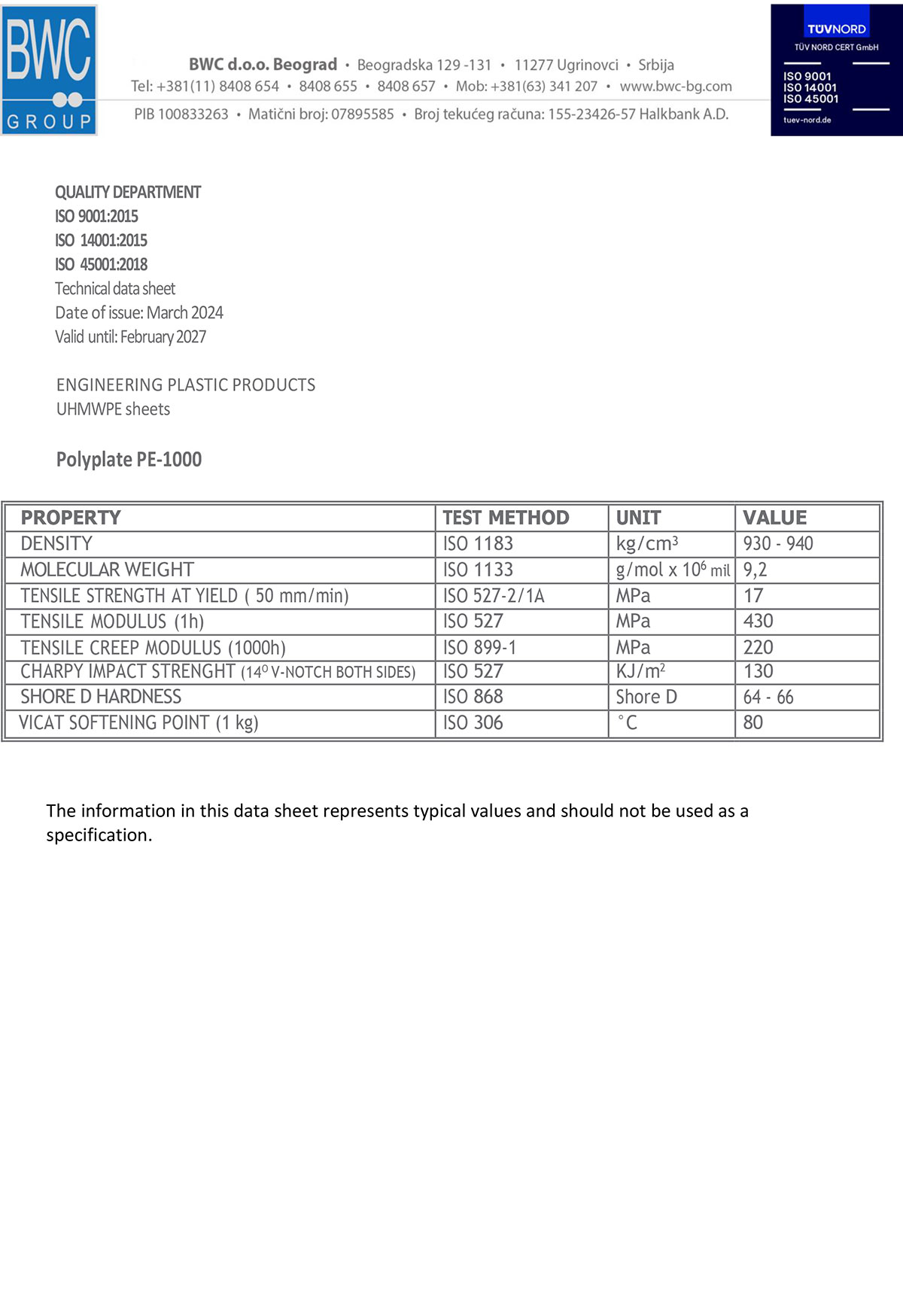

c) Resistance to low and high temperatures, range from -230 º C to 90 º C

d) Resistance to chemicals

e) Sliding properties

Pressed PE 1000 plates do not have welding abilities and are processed as metals.

They are widely used in all branches of industry.

Molecular weight for this material is up to 9000000 g/mol.

Application:

a) Mining and Energy

b) Food and beverage industry

c) Shipping

e) Sports and recreation

e) Chemical industry